ABS has become pretty much standard equipment on most vehicles. Sensors tell a computer when a wheel stops rotating, which indicates—at least when the vehicle still has forward speed—that the brakes have overpowered the available traction at that particular wheel. The computer then directs a hydraulic valve to release some brake fluid pressure to the wheel to let it rotate again. This process repeats many times per second until the vehicle stops or you lift your foot off the brake pedal. The ABS computer does a power-on self test every time you cycle the ignition. If it finds it's lacking data, or a hydraulic pump or valve isn't responding, it illuminates the ABS warning light on the dash. ABS relies on a properly operating conventional brake system. If the ABS packs up, you should still have normal, unassisted braking, so it's safe to continue your journey.

Your ABS light is on. Now what? First, be sure it really is the ABS light and not the light that indicates an issue with your normal service brakes. If you do have a conventional brake issue, like low pedal or grinding noises, this is the wrong Saturday Mechanic for you. Be sure your brakes have adequate lining life, aren't frozen up and are completely free of air. By the way, if you ever need to replace your brake fluid, try as hard as you can to avoid getting air into the ABS controller. It's difficult to bleed, and many require the use of a scan tool to bleed at all. (The scan tool has a function that cycles the pump and valves to move air out of internal passages that can't be bled properly otherwise.)

If the light really is the ABS warning, the first thing to try is to cycle the ignition key off and back on. It's like rebooting your computer—and just maybe whatever transient glitch confused the ABS controller has passed and all is well. If the condition repeats, you need to do some poking and prodding.

You have two options when your ABS light stays on. The first one is to find a shop with a scan tool that will talk to your ABS controller. The dealer will have one, as will some aftermarket shops. For a modest service fee ($50 to $100), a technician will interrogate your ABS controller and look for a trouble code stored in memory. This code will at least give you some idea of where to look.

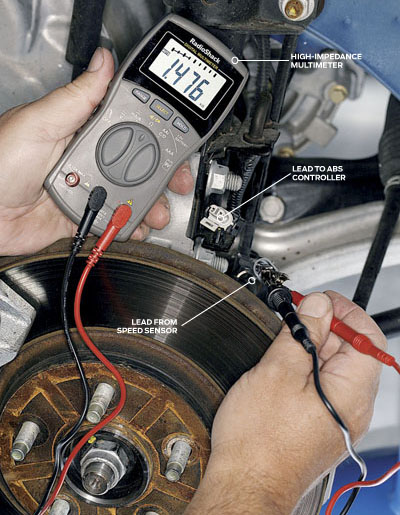

But if you'd like to tear into it yourself and maybe find something simple, you'll need a service manual specific to your car or truck, and simple shop tools, including a high-impedance multimeter. The service manual

is extremely important—if you can't get a paper manual, try subscribing to allda.tadiy.com for service data you can download

On some vehicles, you can access diagnostic trouble codes stored in the computer without using a scan tool. Usually this means pulling a connector and shorting two pins with a small jumper. The ABS warning light will blink on and off in a pattern, corresponding to a trouble code or lack thereof. Obviously, you'll need a Repair Manual to attempt this. Odds are you won't be able to talk the service manager at the dealer into letting you photocopy his manual—but it's worth a try.

Let's say you don't have the trouble code and no information to go on other than an illuminated ABS light. You did check the fuse for the ABS unit, right? This fuse may be in the fuse panel inside the passenger compartment or underhood. Let's not skip the obvious.

Fuse okay? Check the service manual for the voltage and resistance values on various pins and sensors. The main harness to the ABS controller is one place you'll be checking, so while it's apart, give it a shot of aerosol contact cleaner. Inspect carefully for any signs of corrosion—remember that the signals traveling down some of these wires are only millivolts and almost any resistance is a major impediment. If you can, check the resistance across the wheel speed sensors.

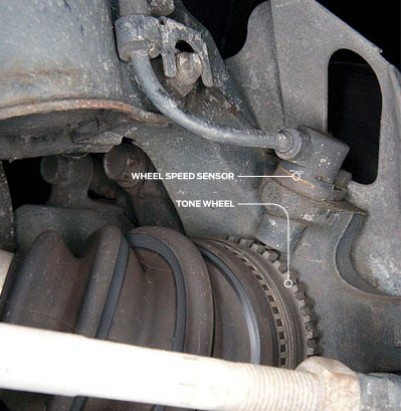

If the ABS controller looks A-Okay, and unplugging and reinserting the main harness didn't help, it's time to eyeball the wheel speed sensors—especially if your ABS issue started right after a trip through that snowbank at the mall or after a high-speed trip down a gravel road. You may have damaged the wiring leading to the ABS sensors or even the tone wheels or sensors themselves. Tone wheel? The ABS controller needs to know how fast each wheel is rotating. Somewhere on each wheel bearing assembly or axle is a toothed wheel, and there's a magnetic pickup positioned immediately next to it. (Exception: Some rwd vehicles use a three-channel system with the tone wheel built into the rear differential.) Because this assembly is out in the open, it's prone to damage from foreign objects.

Loosen the lug nuts or bolts, block the opposite wheel and jack up the car. Inspect the wheel speed sensor's wiring harness and the sensor itself. Some sensors are integrated fairly well into the hub and aren't prone to damage. Others are simply bolted to stamped brackets. If the sensor is loose or missing, or the wires are damaged, you've found your problem. Check the air gap between the sensor and the tone wheel if it's adjustable, the Repair Manual will give you a specific distance the sensor is supposed to be spaced from the tone wheel and directions on how to properly set it. On rare occasions, the tone wheel itself will show damage, such as missing teeth or teeth damaged by road debris. On front-wheel-drive cars, this usually means replacing the stub axle, because the tone wheel is machined directly onto the axle. If the harness to the sensor has a connector in the wheel well, pull it apart and check the sensor for continuity with an ohmmeter. The resistance value can be found in the shop manual. Check for shorts to ground as well. Repair any bad wiring, remembering that there's plenty of mud, snow and salt water flying around in the wheel well.

If you've checked all the sensors and wiring and the ABS light still glows, it's time to throw in the towel and start looking seriously at the ABS controller, an amalgam of hydraulics and electronics that has, as they say, no user-serviceable parts inside. It is, predictably, expensive. Replace it as a last resort.

Consult your service manual for a chart of specific values and pinouts to check against, which should help you narrow down the problem to a specific wire or sensor. This chart is typical.

Antilock Quick Test Check Sheet Using Rotunda 60-pin EEC-IV Breakout Box 0 14-00322 or equivalent Item To Be Tested Ignition Mode Measure Between Pins Tester Scale/Range Specification Pinpoint Test Power Feed Battery Check off batt. Terminals volts 10 minimum ABS ECU Power on 14 + 1 volts 10 minimum DTC B 1318 Pump Motor Power off 2 + 1 volts 10 minimum DTC C 1095 Valve Power off 13 + 1 volts 10 minimum DTC C 1266 Sensor Resistance LF Sensor Resistance off 15 + 16 K ohms 1.28-1.92 K ohms A RF Sensor Resistance off 20 + 7 K ohms 1.28-1.92 K ohms B LR Sensor Resistance off 17 + 18 K ohms 1.28-1.92 K ohms C RR Sensor Resistance off 4 + 19 K ohms 1.28-1.92 K ohms D Sensor Continuity to Ground LF to Ground off 15 + 1 continuity no continuity A RF to Ground off 20 + 1 continuity no continuity B LR to Ground off 17 + 1 continuity no continuity C RR to Ground off 4 + 1 continuity no continuity D Sensor Output Voltage

Rotate Wheels at One Revolution Per SecondLF Sensor Output off 15 + 16 AC mV > 100 mV A RF Sensor Output off 20 + 7 AC mV > 100 mV B LR Sensor Output off 17 + 18 AC mV > 100 mV C RR Sensor Output off 4 + 19 AC mV > 100 mV D ABS Warning Lamp Check on 22 + 1 volts 10V minimum E Stoplamp Switch Check Brake Pedal Applied off 9 + 1 volts 10 minimum Brake Pedal Released off 9 + 1 continuity no continuity